Products

Home > AST Homemade Produc... > Carbide Endmills > Endmill Radius > REM Carbide EndMil... > REM4-ST

|

|

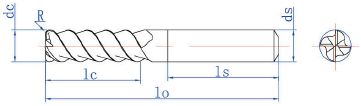

REM Solid Carbide Corner Radius End Mill with Four Cutting Edges -- Economical Type

Features:

1、All dimension is fixed by our norm and also accept non standard order.

2、Tolerance of dc≤3mm 0/-0.02, dc>3mm 0/-0.03

3、Tolerance of shank h6

4、Cutting edge to center with tip angle

5、Helix angle 35°

6、Tolerance of corner R±0.02

Universal Endmills-High-performance Type/Basic Type/Economical Type

Application Variety

Features--of HTA Series High-performance Endmills:

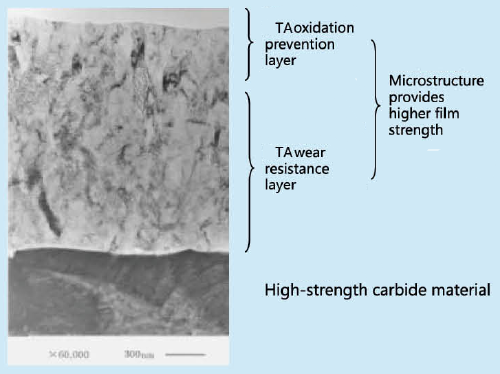

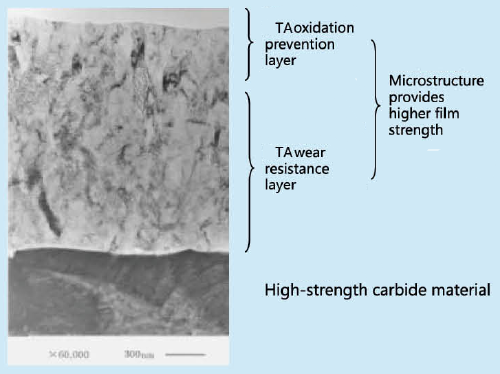

□ Carefully selected High-strength carbide and coating cemented carbide, improve the oxidation resistance, heat resistance, wear resistance.

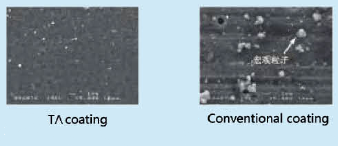

□ Fewer macroparticles on film surface result in improved smoothness. Reduced abrasion and better deposition resistance improved wear and adhesion resistance.

□ Unique geometry improves chip removal and tools rigidity. So the tools can machine≤HRC55 following materials: stainless steel, heat-resistant alloys, titanium, nickel alloys, cast iron, copper alloys, etc.

□ High performance carbide material ensure longer tool life and high efficiency.

Features--of STA Series Basic Type Endmills:

□ Carefully selected High-strength carbide and coating cemented carbide, improve the oxidation resistance, heat resistance, wear resistance.

□ Superior chipping, wear resistance,and better surface roughness from special cutting edge and margin shape .

□ Aplly to very wide work materials.

□ STA:economical and high performance carbide meterial.

Features--of ST Series Economical Type Endmills:

□ Better heat and wear resistance from ST coating for a long life.

□ Aplly to very wide work materials.

□ Superior chipping, wear resistance,and better surface roughness from special cutting edge and margin shape .

□ Economical and high performance carbide material.

Application Work Material:

| Series | Work Material | |||||||||||||

| Structural Steel | Carbon Steel | Alloy Steel | Pre-hardened Steel | Hardened Steel | Stainless Steel | Titanium Alloys, Nickel Alloys | Cast Irons | Aluminum Alloys | Copper Alloys | Plastic | ||||

| HRC30-45 | HRC45-55 | HRC55-60 | >HRC60 | |||||||||||

| ST |

◎ |

◎ |

◎ |

◎ |

◎ |

|

|

|

○ |

|

○ |

|

○ |

|

| STA | ◎ | ◎ | ◎ | ◎ | ◎ |

○ |

◎ |

○ |

◎ |

|

○ |

|

||

| HTA |

◎ |

◎ |

◎ |

◎ |

◎ |

◎ |

|

|

◎ |

◎ |

◎ |

|

○ |

|

(◎ Most Suitable ○ Suitable)

Difference between ST/STA/HTA Series:

| Series | Design of cutting edge | Carbide Material | Coating |

| ST | Unique shape of cutting edge suitable for very wide work materials | Economical carbide material | Economical universal coating |

| STA | Unique shape of cutting edge suitable for very wide work materials | Normal carbide material | High-performance coating especially suitable for endmills |

| HTA | Unique shape of cutting edge suitable for very wide work materials | High-performance carbide material | High-performance coating especially suitable for endmills |

Type available and Diameter ranges

EM2:D1.5~32.0mm EM3:D2.0~32.0mm EM4:D4.0~32.0mm

LEM2:D2.0~4.0mm LEM4:D2.0~6.0mm

REM2:D1.0~20.0mm REM4:D3.0~20.0mm

LREM2:D2.0~6.0mm LREM4:D3.0~12.0mm

BEM2:R1.0~6.0mm BEM3:R2.0~16.0mm BEM4:R2.0~16.0mm

LBEM2:R1.0~2.0mm

| Economical type Order No. | Cutting Edge Diameter | Flute Length | Shank Diameter | Overall Length | Corner Radius |

| ST Series (Coating) | dc | lc | ds | lo | R |

| REM403003ST | 3.0 | 10 | 6 | 45 | 0.3 |

| REM403005ST | 3.0 | 10 | 6 | 45 | 0.5 |

| REM403008ST | 3.0 | 10 | 6 | 45 | 0.8 |

| REM404002ST | 4.0 | 12 | 6 | 45 | 0.2 |

| REM404003ST | 4.0 | 12 | 6 | 45 | 0.3 |

| REM404005ST | 4.0 | 12 | 6 | 45 | 0.5 |

| REM404010ST | 4.0 | 12 | 6 | 45 | 1.0 |

| REM405002ST | 5.0 | 15 | 6 | 50 | 0.2 |

| REM405003ST | 5.0 | 15 | 6 | 50 | 0.3 |

| REM405005ST | 5.0 | 15 | 6 | 50 | 0.5 |

| REM405010ST | 5.0 | 15 | 6 | 50 | 1.0 |

| REM405012ST | 5.0 | 15 | 6 | 50 | 1.2 |

| REM406002ST | 6.0 | 15 | 6 | 50 | 0.2 |

| REM406003ST | 6.0 | 15 | 6 | 50 | 0.3 |

| REM406005ST | 6.0 | 15 | 6 | 50 | 0.5 |

| REM406010ST | 6.0 | 15 | 6 | 50 | 1.0 |

| REM408005ST | 8.0 | 20 | 8 | 60 | 0.5 |

| REM408010ST | 8.0 | 20 | 8 | 60 | 1.0 |

| REM408015ST | 8.0 | 20 | 8 | 60 | 1.5 |

| REM408020ST | 8.0 | 20 | 8 | 60 | 2.0 |

| REM408025ST | 8.0 | 20 | 8 | 60 | 2.5 |

| REM410005ST | 10.0 | 25 | 10 | 70 | 0.5 |

| REM410010ST | 10.0 | 25 | 10 | 70 | 1.0 |

| REM410015ST | 10.0 | 25 | 10 | 70 | 1.5 |

| REM410020ST | 10.0 | 25 | 10 | 70 | 2.0 |

| REM410025ST | 10.0 | 25 | 10 | 70 | 2.5 |

| REM410030ST | 10.0 | 25 | 10 | 70 | 3.0 |

| REM412005ST | 12.0 | 25 | 12 | 75 | 0.5 |

| REM412010ST | 12.0 | 25 | 12 | 75 | 1.0 |

| REM412015ST | 12.0 | 25 | 12 | 75 | 1.5 |

| REM412020ST | 12.0 | 25 | 12 | 75 | 2.0 |

| REM412025ST | 12.0 | 25 | 12 | 75 | 2.5 |

| REM412030ST | 12.0 | 25 | 12 | 75 | 3.0 |

| REM416010ST | 16.0 | 32 | 16 | 110 | 1.0 |

| REM416020ST | 16.0 | 32 | 16 | 110 | 2.0 |

| REM416030ST | 16.0 | 32 | 16 | 110 | 3.0 |

| REM416040ST | 16.0 | 32 | 16 | 110 | 4.0 |

| REM416050ST | 16.0 | 32 | 16 | 110 | 5.0 |

| REM420010ST | 20.0 | 38 | 20 | 110 | 1.0 |

| REM420020ST | 20.0 | 38 | 20 | 110 | 2.0 |

| REM420030ST | 20.0 | 38 | 20 | 110 | 3.0 |

| REM420040ST | 20.0 | 38 | 20 | 110 | 4.0 |

| REM420050ST | 20.0 | 38 | 20 | 110 | 5.0 |