Products

Home > AST Homemade Produc... > Carbide Endmills > Endmill Ball > LBEM Long Neck Bal... > LBEM2-HS

|

|

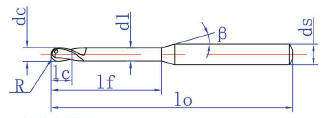

LBEM Long Neck Solid Carbide Ball End Mill with Two Cutting Edges --- High Hardness Processing Type

Features:

1、All dimension is fixed by our norm and also accept non standard order.

2、Tolerance of dc 0/-0.015

3、Tolerance of shank h6

4、Tolerance of R ±0.005;

5、Helix

angle 35°.

6、Shank taper angle β=16°.

Universal Endmills-High Hardness Processing Milling

Features:

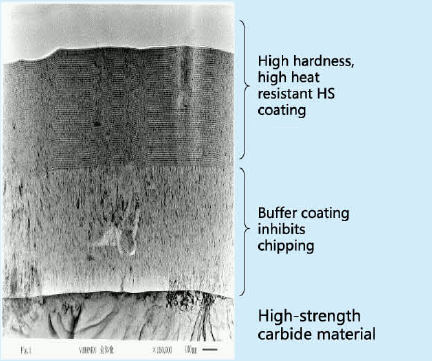

□ Carefully selected super high hardness carbide and super heat-resistant HS coating, the milling has superior heat resistance, so all heat-treated material of HRC65 below can be machined.

□ High hardness and ultrafine particles low-Co cemented carbide, tiny plastic deformation effectively suppressed produced ultra high-speed processing, improved tool life.

□ Using special grinding tool technology to achieve a high shape accuracy and dimensional accuracy, high precision machining can be performed.

Application Work Material:

| Series | Work Material | |||||||||||||

| Structural Steel | Carbon Steel | Alloy Steel | Pre-hardened Steel | Hardened Steel | Stainless Steel | Titanium Alloys, Nickel Alloys | Cast Irons | Aluminum Alloys | Copper Alloys | Plastic | ||||

| HRC30-45 | HRC45-55 | HRC55-60 | >HRC60 | |||||||||||

| HS |

○ |

○ |

○ |

○ |

○ |

◎ |

◎ |

◎ |

○ |

○ |

○ |

|

◎ |

|

(◎ Most Suitable ○ Suitable)

Type available and Diameter ranges

EM2-HS:D1.5~12.0mm EM4-HS:D1.0~12.0mm

LEM2-HS:D0.1~4.0mm LEM4-HS:D1.0~6.0mm

LREM2-HS:D0.5~6.0mm LREM4-HS:D1.0~12.0mm

BEM2-HS:R0.05~6.0mm BEM4-HS:R1.0~6.0mm

LBEM2-HS:R0.1~2.0mm

| High Hardness Processing type Order No. | Spherical Radius | Cutting Edge Length | Effective Length | Neck Diameter | Shank Diameter | Overall Length |

| HS Series (Coating) | R | lc | lf | dn | ds | lo |

| LBEM2002005HS | 0.1 | 0.16 | 0.5 | 0.17 | 4 | 45 |

| LBEM2002010HS | 0.1 | 0.16 | 1 | 0.17 | 4 | 45 |

| LBEM2003010HS | 0.15 | 0.24 | 1 | 0.27 | 4 | 45 |

| LBEM2003020HS | 0.15 | 0.24 | 2 | 0.27 | 4 | 45 |

| LBEM2004010HS | 0.2 | 0.32 | 1 | 0.37 | 4 | 45 |

| LBEM2004020HS | 0.2 | 0.32 | 2 | 0.37 | 4 | 45 |

| LBEM2004030HS | 0.2 | 0.32 | 3 | 0.37 | 4 | 45 |

| LBEM2004040HS | 0.2 | 0.32 | 4 | 0.37 | 4 | 45 |

| LBEM2005020HS | 0.25 | 0.4 | 2 | 0.47 | 4 | 45 |

| LBEM2005030HS | 0.25 | 0.4 | 3 | 0.47 | 4 | 45 |

| LBEM2005040HS | 0.25 | 0.4 | 4 | 0.47 | 4 | 45 |

| LBEM2006020HS | 0.3 | 0.48 | 2 | 0.57 | 4 | 45 |

| LBEM2006030HS | 0.3 | 0.48 | 3 | 0.57 | 4 | 45 |

| LBEM2006040HS | 0.3 | 0.48 | 4 | 0.57 | 4 | 45 |

| LBEM2006060HS | 0.3 | 0.48 | 6 | 0.57 | 4 | 45 |

| LBEM2008020HS | 0.4 | 0.64 | 2 | 0.77 | 4 | 45 |

| LBEM2008040HS | 0.4 | 0.64 | 4 | 0.77 | 4 | 45 |

| LBEM2008060HS | 0.4 | 0.64 | 6 | 0.77 | 4 | 45 |

| LBEM2010030HS | 0.5 | 0.8 | 3 | 0.95 | 4 | 45 |

| LBEM2010040HS | 0.5 | 0.8 | 4 | 0.95 | 4 | 45 |

| LBEM2010050HS | 0.5 | 0.8 | 5 | 0.95 | 4 | 45 |

| LBEM2010060HS | 0.5 | 0.8 | 6 | 0.95 | 4 | 45 |

| LBEM2010080HS | 0.5 | 0.8 | 8 | 0.95 | 4 | 45 |

| LBEM2010100HS | 0.5 | 0.8 | 10 | 0.95 | 4 | 45 |

| LBEM2015060HS | 0.75 | 1.2 | 6 | 1.43 | 4 | 45 |

| LBEM2015080HS | 0.75 | 1.2 | 8 | 1.43 | 4 | 45 |

| LBEM2015100HS | 0.75 | 1.2 | 10 | 1.43 | 4 | 45 |

| LBEM2015120HS | 0.75 | 1.2 | 12 | 1.43 | 4 | 45 |

| LBEM2015160HS | 0.75 | 1.2 | 16 | 1.43 | 4 | 50 |

| LBEM2020060HS | 1.5 | 1.6 | 6 | 1.93 | 4 | 45 |

| LBEM2020080HS | 1.5 | 1.6 | 8 | 1.93 | 4 | 45 |

| LBEM2020100HS | 1.5 | 1.6 | 10 | 1.93 | 4 | 45 |

| LBEM2020120HS | 1.5 | 1.6 | 12 | 1.93 | 4 | 45 |

| LBEM2020140HS | 1.5 | 1.6 | 14 | 1.93 | 4 | 50 |

| LBEM2020160HS | 1.5 | 1.6 | 16 | 1.93 | 4 | 50 |

| LBEM2030060HS | 1.5 | 2.4 | 6 | 2.9 | 3 | 60 |

| LBEM2030080HS | 1.5 | 2.4 | 8 | 2.9 | 6 | 60 |

| LBEM2030100HS | 1.5 | 2.4 | 10 | 2.9 | 6 | 60 |

| LBEM2030120HS | 1.5 | 2.4 | 12 | 2.9 | 6 | 60 |

| LBEM2030140HS | 1.5 | 2.4 | 14 | 2.9 | 6 | 60 |

| LBEM2030160HS | 1.5 | 2.4 | 16 | 2.9 | 6 | 60 |

| LBEM2030200HS | 1.5 | 2.4 | 20 | 2.9 | 6 | 70 |

| LBEM2040080HS | 2.0 | 3.2 | 8 | 3.9 | 4 | 70 |

| LBEM2040100HS | 2.0 | 3.2 | 10 | 3.9 | 6 | 70 |

| LBEM2040120HS | 2.0 | 3.2 | 12 | 3.9 | 6 | 70 |

| LBEM2040160HS | 2.0 | 3.2 | 16 | 3.9 | 6 | 70 |

| LBEM2040200HS | 2.0 | 3.2 | 20 | 3.9 | 6 | 70 |

| LBEM2040250HS | 2.0 | 3.2 | 25 | 3.9 | 6 | 70 |